Join us on an exclusive journey as we step into the heart of one of the world’s largest chocolate manufacturers, revealing the fascinating process behind the creation of over 7 million bars each day.

Dive into the golden era of chocolate in 1935 when KitKat made its grand entrance into the market. Comprising three layers of wafer and two layers of luscious filling, all embraced by a layer of heavenly chocolate, it’s a harmonious blend of crispy wafers and silky milk chocolate. As the 1930s witnessed a drop in chocolate prices, making it accessible to 90% of the population, a fierce chocolate war erupted among giants like Mars and Cadbury.

Fast forward to 1988, when Nestle acquired the beloved brand in the U.K. One of Nestle’s bustling factories, located in York, orchestrates the production of over 7 million KitKat bars daily.

The Art and Science Behind KitKat

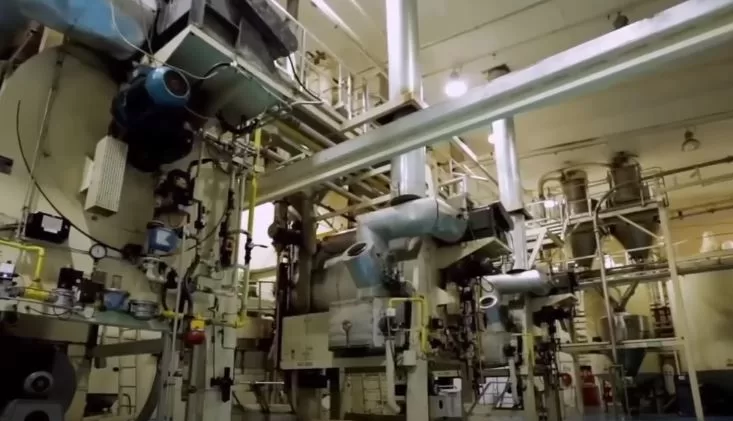

Embark on a sweet journey as we unveil the intricate process behind the creation of KitKat, where every step is a carefully orchestrated dance of flavors. Nestled in a strategically organized factory, the magic happens as cocoa beans from West Africa transform into the beloved KitKat bars we all adore.

The cocoa adventure commences with sun-drying the beans for seven days, followed by a direct journey to the York production site. A meticulous three-hour process ensues, involving cleaning, husking, and vibrating filters that separate husks and pulps. The cocoa beans then undergo a tantalizing transformation, with roasting being a closely guarded secret among chocolate maestros.

Transformation of Cocoa Beans into the Irresistible KitKat Magic

Enter the giant roaster, where pressure and heat release the chocolate treasure, known as chocolate liquor. After separating cocoa butter and solids, the latter becomes the cocoa powder we find in supermarkets. The chocolate alchemy begins with the melding of cocoa butter, cocoa powder, sugar, milk, and vegetable fats. Yes, vegetable fats reduce costs, but they don’t diminish the irresistible allure of the final product.

The one-ton mixer swirls these ingredients into a sweet, thick, sandy chocolate paste, marking the beginning of the perfection process. Enter “conching,” where chocolate particles are ground to perfection, resulting in the smooth and creamy texture we all crave. The longer the conching, the creamier, tastier, and, yes, pricier the chocolate.

Luscious chocolate ready for its KitKat destiny

Once the liquid chocolate is ready, precision takes the spotlight. Heating raises the temperature before cooling it down to 27 degrees Celsius, preventing crystallization that mars chocolate’s visual appeal. Now, we have the chocolate ready for Kitkat bars.

But the adventure doesn’t end there; it’s time to craft the wafer layers. Flour and water combine to form a dough that takes shape in molds, destined to become large wafer sheets. Baked at 150 degrees, the wafer sheets cool down before receiving layers of filling. It’s a delicate dance as one layer of filling meets another wafer, creating a scrumptious three-layered sandwich.

But the adventure doesn’t end there; it’s time to craft the wafer layers. Flour and water combine to form a dough that takes shape in molds, destined to become large wafer sheets. Baked at 150 degrees, the wafer sheets cool down before receiving layers of filling. It’s a delicate dance as one layer of filling meets another wafer, creating a scrumptious three-layered sandwich.

The secret of the filling is revealed

A blend of cocoa liquor, sugar, and a touch of crushed KitKat. Surprisingly, rejected KitKat bars find redemption, crushed into a paste that becomes the filling for other KitKats. It’s a sustainable and delicious twist to the KitKat tale. In every crispy bite, KitKat whispers the story of its journey, from cocoa bean to iconic bar.

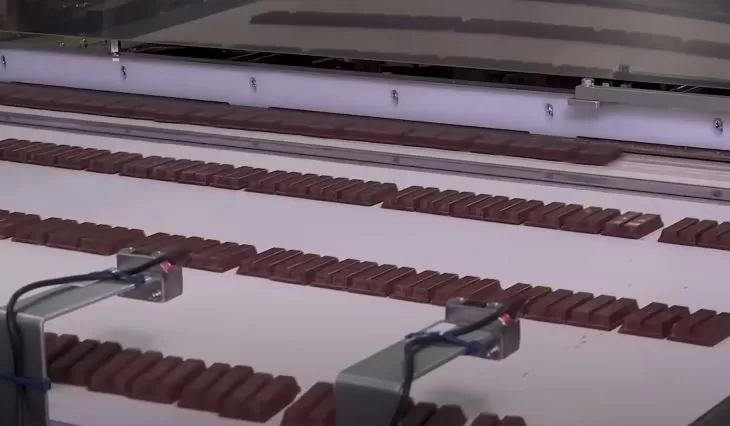

The grand finale begins after 16 hours of meticulous mixing, where the chocolate emerges ready to take center stage as bars. Picture this: a machine that fills a mind-boggling 336 molds per minute, translating into over 200,000 chocolate bars each day. The chocolate cascades into molds, enveloping the wafer interior, and a final chocolate layer cloaks them in sweet harmony.

From Cooling Bliss to Packaging Perfection

In a chilled haven, the bars gracefully part ways with the molds, making a swift passage through the cooling tunnel that bestows a satisfying snap to the chocolate. But the perfection quest doesn’t end there—quality controllers swoop in to eliminate any flawed bars, ensuring only the finest make it to your eager hands. Those rejected gems? Crushed and mingled with chocolate to become the secret filling that elevates the KitKat experience.

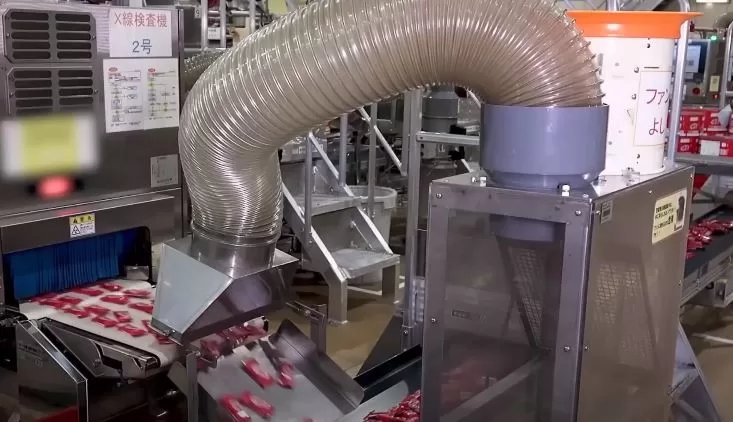

Packaging, a symphony of automated precision, follows suit. Swift robots choreograph the wrapping, creating a visual masterpiece before your very eyes. A decorative wrapper is the final touch, and voilà, the bars are poised to embark on a mouth-melting journey. Brace yourself for this staggering statistic: a staggering 7 million bars dance through this process every single day.

Packaging, a symphony of automated precision, follows suit. Swift robots choreograph the wrapping, creating a visual masterpiece before your very eyes. A decorative wrapper is the final touch, and voilà, the bars are poised to embark on a mouth-melting journey. Brace yourself for this staggering statistic: a staggering 7 million bars dance through this process every single day.

Post-packaging, the KitKat wonders find sanctuary in a storage building, eagerly awaiting their moment to shine on supermarket shelves. Fully adorned and ready for adventure, these bars are transported to an on-site storage facility, primed and prepared for the moment an order is placed.

With each new order, the bars elegantly glide to the loading area, ready to embark on a global journey to tantalize taste buds and bring joy to chocolate enthusiasts around the world. The KitKat magic, meticulously crafted and swiftly dispatched, awaits to sweeten your day.

Conclusion

In conclusion, indulging in KitKat isn’t merely enjoying a chocolate bar; it’s a global celebration of meticulous craftsmanship and rich heritage. From the chocolate’s origin in the 1930s to Nestle’s modern York factory producing over 7 million bars daily, KitKat’s journey is a testament to its enduring allure.

The art and science behind how KitKat sells 7 million chocolates daily is now clear to you. From cocoa beans transforming into chocolate to the intricate dance of crafting wafer layers. Every rejected bar finds purpose in the secret filling, ensuring sustainability and adding a unique twist to the KitKat tale. As these millions of bars embark on a global journey, the KitKat magic awaits to sweeten the world’s collective palate.

Related search:

Nestle launches new limited edition KitKat for 2024